Surimi is processed from natural fish through pretreatment, fish meat processing, rinsing, dewatering and other steps. In the traditional surimi processing process, it is necessary to rinse the minced fish meat for many times to remove soluble protein and other impurities. However, after rinsing, the fish fiber needs to be dewatered in the screw dehydrator several times to achieve the required water content. About 45% of fish fiber will be lost in the process, which greatly reduces the economic benefits.

More and more surimi processing enterprises in the United States, Canada and Southeast Asia, such as Thailand, have replaced the traditional surimi processing technology with centrifugal separation technology. By using horizontal decanter centrifuge, the rinsing water has been reduced, and the final yield of surimi reached 75%, thus greatly improved the economic benefits.

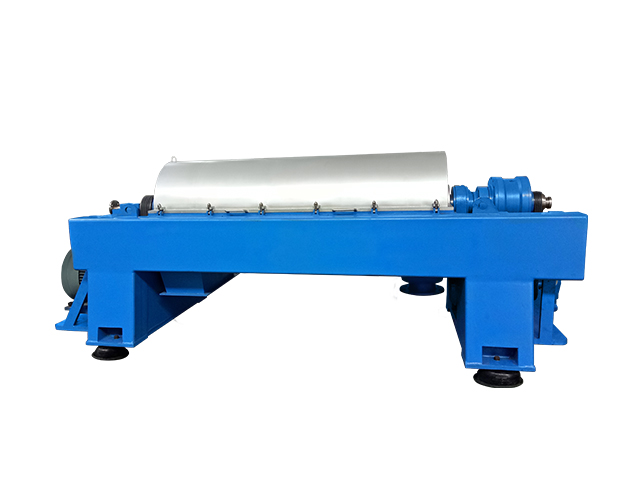

1. Surimi processing with horizontal decanter centrifuge

After the minced fish was mixed with precooled water and rinsed in a rinsing tank, it will be pumped to a fine filter. After fine filtration, the surimi will be pumped into the horizontal decanter centrifuge for dewatering. Due to the automatic control system of dryness in the centrifuge, after dewatering, the humidity of the dewatered surimi is less than 82%. Then the dewatered surimi will be mixed with the refrigerant or other additives in the mixer, and sent to the extruder for molding.

2. Principle of horizontal decanter centrifuge

The surimi will be fed into the drum through the feed inlet, then the drum will gradually accelerate to 4000 r/min. Under the action of centrifugal force, the fish fiber will settle on the inner wall of the drum, and be pushed to the slag outlet by the continuous rotating screw conveyor. The conveying capacity depends on the speed difference between the drum and the screw conveyor. At the same time, the clarified rinse water will be discharged from the liquid outlet.

In order to meet the requirements of balanced dryness of the surimi, the horizontal decanter centrifuge is equipped with automatic dryness control system. The system is:according to the different solid content in the surimi, adjust the speed difference between the drum and the screw conveyor, so as to achieve the same moisture content of the surimi.

3. Characteristics

Compared with the traditional surimi processing technology, centrifugal separation technology has the following advantages:

(1) The yield of surimi increased by 25%.

(2) Due to its closed mixing system, it is convenient to monitor the water consumption accurately.

(3) It is easy to adjust the processing capacity of the production line according to the production requirement.

(4) The start-up time and shutdown time can be reduced.

(5) It can deal with different kinds of fish with different fat content.

(6) Due to the automatic cleaning system, the quality of the surimi will be improved.

(7) The production line covers only a quarter of the area of the traditional process.

(8) Need less workers.

4. Conclusion

In the traditional surimi processing line, the fish fiber in the rinse water can also be recovered by adding a horizontal decanter centrifuge, or replace the original dehydrator with horizontal decanter centrifuge.