Product Features

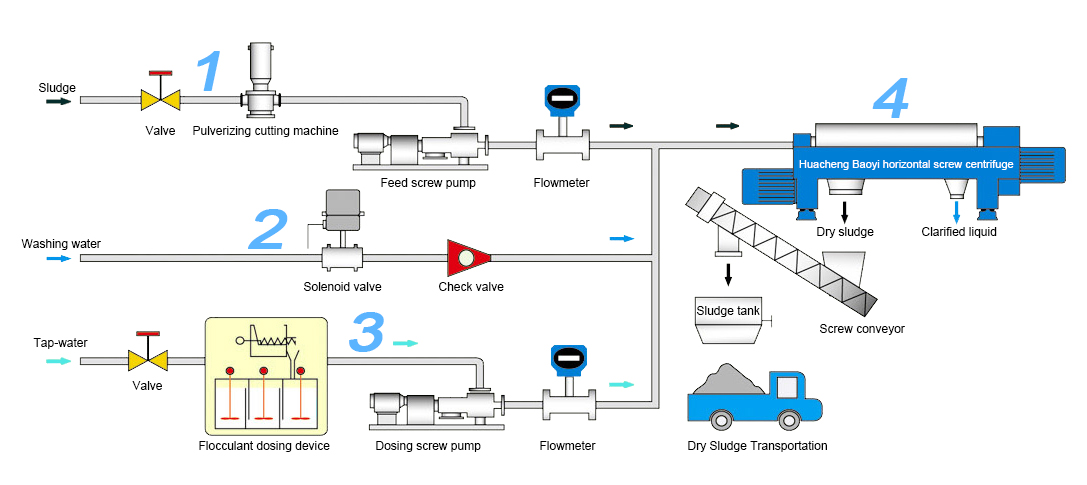

Horizontal decanter centrifuge is a kind of mechanical equipment for continuous separation of suspension containing density difference by centrifugal settling principle. Our company's centrifuge can clarify, dehydrate or separate suspensions containing solid particles of 0.002-3mm in diameter and 0.5-40% in concentration range. According to material features, it can be divided into LW two-phase horizontal decanter centrifuge and LWS three-phase horizontal decanter centrifuge. It can be used to separate different materials under different working conditions, and is widely used in pharmaceutical, food, chemical, environmental protection and other industries.

The product has the following features:

1. The design and manufacture of horizontal decanter centrifuge meet the requirements of JB/T502-2004 screw discharge settling centrifuge and JB8525-1997 centrifuge safety requirements. It has high speed, high separation factor and large length-diameter ratio. The separation speed is generally above 3000r/min and the separation factor is above 2500.

2. All the parts that may contact the material are made of high-quality high-strength austenitic stainless steel or duplex stainless steel, which have sufficient strength and excellent corrosion resistance, and have been stress eliminated for many times.

3. The drum body has large aspect ratio, high rotational speed and a variety of angle drum cone structure.

4. The screw pusher is made by special molding method, with small screw pitch error and small blade deformation. The screw pushing surface adopts special anti-wear measures, spraying and welding cemented carbide or inlaying cemented carbide wear-resistant sheets, so it is anti-corrosion and wear-resistant and has long service life.

5. The differential system has reliable performance. This series of centrifuge differential generally adopts planetary gear or cycloidal pinwheel differential. According to the needs, it can also be equipped with full hydraulic differential system. Mechanical differential generally adopts domestic well-known brand, hydraulic differential system adopts imported brand. The differential has high manufacturing accuracy, good performance and reliable operation.

6. The horizontal decanter centrifuge with BD baffle, has deepened the liquid pool. It can concentrate and dehydrate various primary sedimentation sludge and residual activated sludge in different proportions, and efficiently separate some hard-to-separate materials.

7. The main motor and the auxiliary motor are controlled by frequency converter to realize stepless speed regulation, which has wide adaptability to materials and simple debugging.

8. The centrifuge adopts reasonable tolerance control and advanced processing technology. The centrifuge uses precision dynamic balancing of double rotor and adopts imported SKF bearings. Therefore, the vibration of both ends of the centrifuge bearings is kept within 2.5mm/s when the centrifuge leaves the factory (national standard excellent grade).

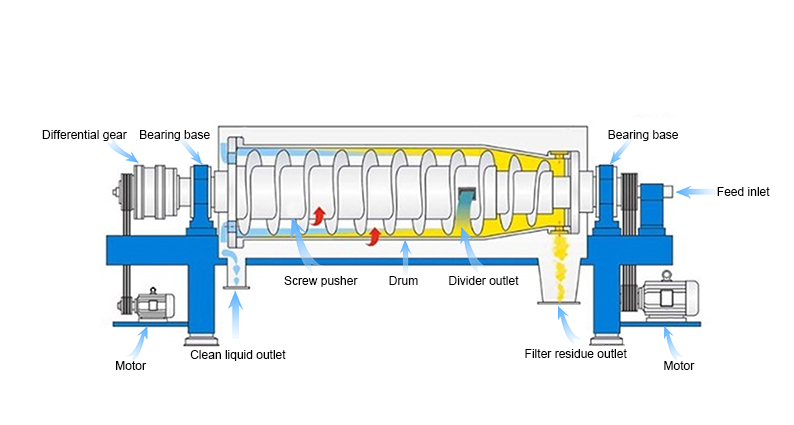

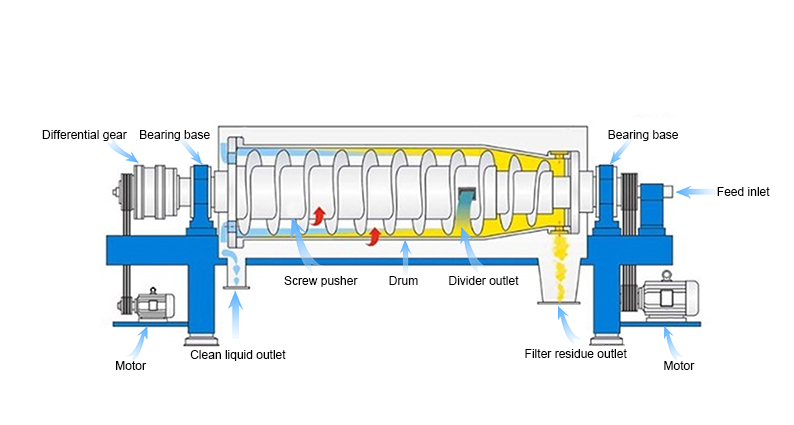

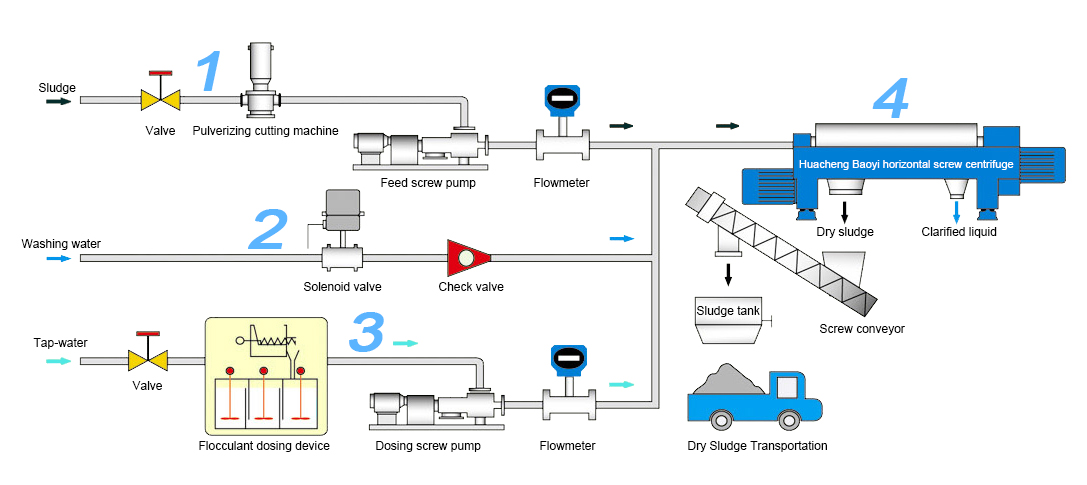

Operating Principle

Horizontal decanter centrifuge is mainly composed of conical drum, screw pusher, differential system, bearing base, frame, housing, main and auxiliary motor and electrical system. The main motor drives the drum and the secondary motor drives the planetary gear differential, which generates the drum and spiral differential. Under the strong centrifugal force produced by the high-speed rotation, the centrifuge can be separated continuously.

The drum and the screw pusher rotate at a certain differential speed and high speed. The material continuously enters the spiral feeding chamber from the feeding tube, and then accelerates and enters the drum. Under the action of centrifugal force field, the heavier solid phase deposits on the drum wall to form the sediment layer. The solid deposits are continuously pushed to the cone end of the drum by the screw pusher, and discharged from the slag discharge outlet after drying in the drying zone. The lighter liquid phase forms an inner liquid ring, which continuously overflows the drum from the overflow outlet at the large end of the drum and discharges out of the machine through the outlet.

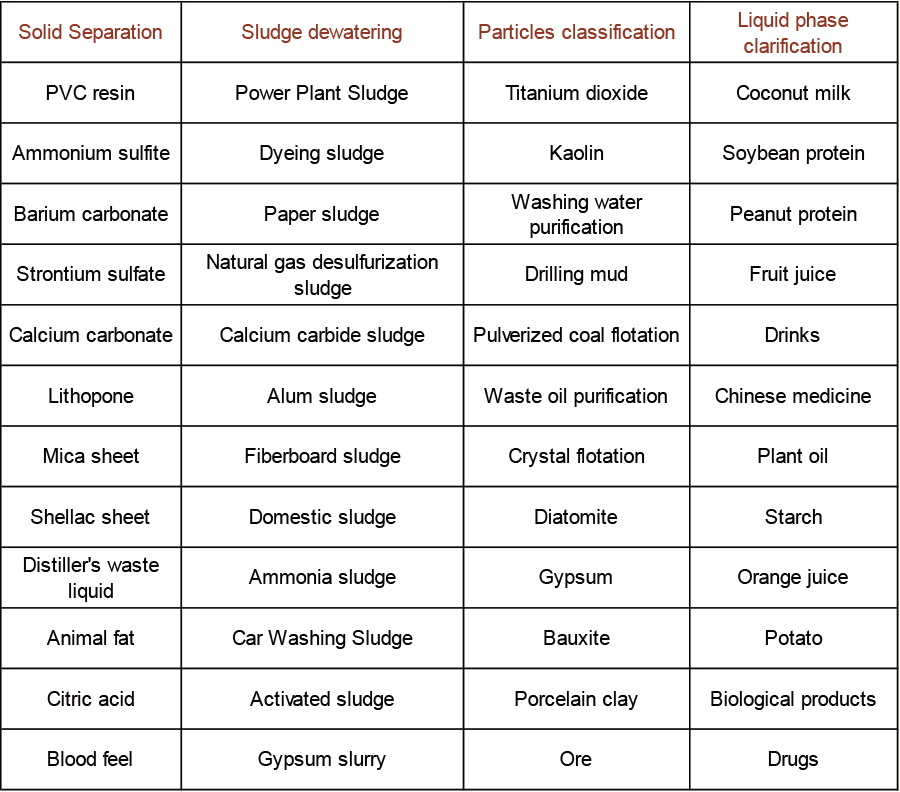

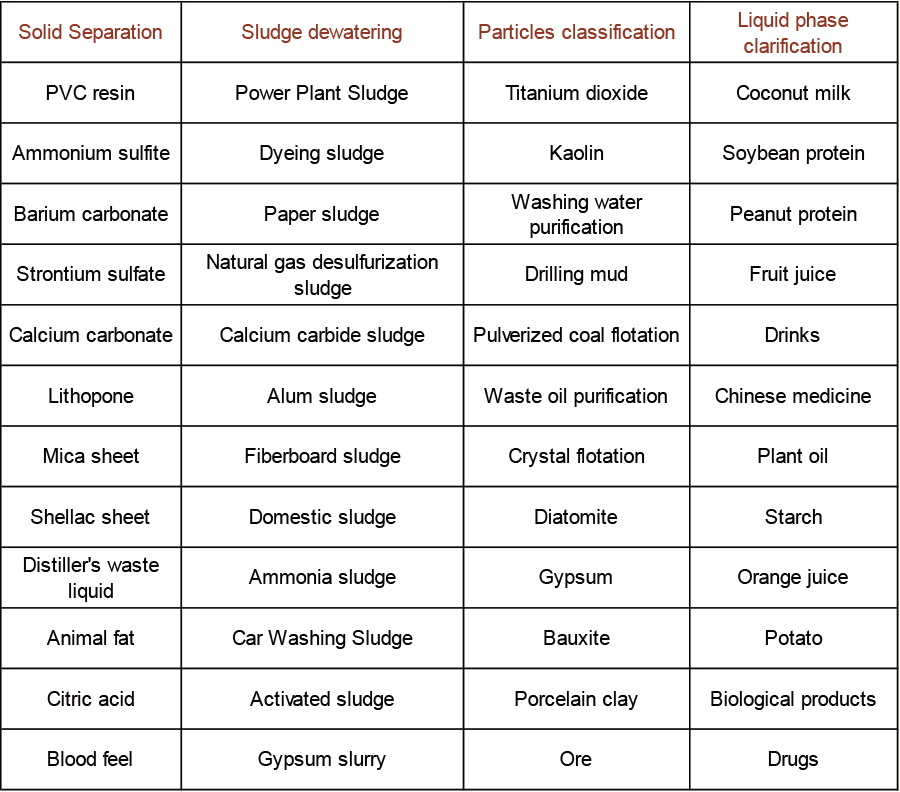

Application Fields

Horizontal screw centrifuge is suitable for processing polyvinyl chloride resin, ammonium sulfite, barium carbonate, strontium sulfate, lithopone, starch, diatomite, gypsum, bauxite, soybean protein, peanut protein, fruit juice, beverage, vegetable oil, citric acid, blood powder, titanium dioxide, kaolin, drilling mud, etc. At the same time, it is applied to clean coal dehydration, pulverized coal dehydration, waste oil purification, mineral classification, municipal sewage treatment, as well as power plant sludge, printing and dyeing sludge, paper sludge and other industrial wastewater treatment fields.