Introduction

In industries where oil production, refining, and processing are prevalent, the management of oil sludge is a significant challenge. This byproduct, a mix of water, oil, and solid particles, is difficult to handle due to its complex composition. Effective dewatering of oil sludge is crucial for reducing its volume, recovering valuable oil, and minimizing environmental impact. The decanter centrifuge has emerged as a key technology in addressing these challenges, offering an efficient and reliable method for oil sludge dewatering. This article explores the role of decanter centrifuges in handling oil sludge, their operational principles, and their diverse applications in the oil and gas industry.

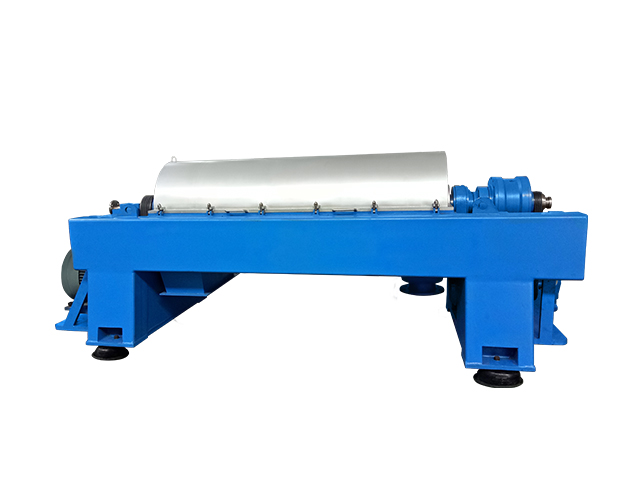

Understanding Decanter Centrifuges

A decanter centrifuge is a type of centrifuge used to separate solid particles from liquids in a slurry or sludge. It operates based on the principle of centrifugal force, where the rotating bowl of the centrifuge spins at high speeds, causing the denser solid particles to move outward towards the bowl's wall, while the less dense liquid phase remains closer to the center. The continuous operation of the centrifuge, facilitated by a screw conveyor inside the bowl, ensures that separated solids are discharged from one end, while the clarified liquid exits from the other.

Oil Sludge and the Need for Dewatering

Oil sludge is a waste material generated during the exploration, extraction, refining, and storage of oil. It consists of a mixture of crude oil, water, and solid particles like sand, silt, and other contaminants. The management of oil sludge is critical for several reasons:

Environmental Impact: Improper disposal of oil sludge can lead to severe environmental pollution, contaminating soil and water sources.

Resource Recovery: Oil sludge contains recoverable oil, which, if extracted, can be reused, thus reducing waste and enhancing resource efficiency.

Volume Reduction: Dewatering oil sludge reduces its volume, making it easier and more cost-effective to handle, transport, and dispose of.

Role of Decanter Centrifuges in Oil Sludge Dewatering

Decanter centrifuges play a pivotal role in the dewatering process of oil sludge. Their ability to separate solids from liquids with high efficiency makes them ideal for this application. Here's how they contribute to the dewatering of oil sludge:

1. High-Efficiency Separation

Decanter centrifuges are designed to handle the complex composition of oil sludge, effectively separating the oil, water, and solid particles. The centrifugal force generated within the rotating bowl ensures that even fine particles are separated, leading to a clearer liquid phase and a drier solid phase. This high level of separation efficiency is essential for reducing the water content in the sludge and recovering valuable oil.

2. Continuous Operation

One of the significant advantages of decanter centrifuges is their ability to operate continuously. In industrial settings, where large volumes of oil sludge are generated, this continuous operation ensures that the dewatering process keeps pace with production, preventing bottlenecks and maintaining operational efficiency.

3. Versatility in Handling Different Sludge Types

Oil sludge can vary in composition depending on the source and processing method. Decanter centrifuges offer the flexibility to handle different types of sludge, whether it is generated from crude oil storage tanks, refineries, or drilling operations. Adjustments in the centrifuge's operational parameters allow it to efficiently process sludge with varying characteristics, ensuring optimal separation and dewatering.

4. Reduced Environmental Impact

By efficiently dewatering oil sludge, decanter centrifuges contribute to reducing the environmental footprint of oil-related industries. The drier sludge is easier to dispose of or treat further, while the recovery of oil from the sludge minimizes waste. This process not only supports environmental sustainability but also aligns with regulatory requirements for waste management.

Applications of Decanter Centrifuges in the Oil and Gas Industry

Decanter centrifuges are widely used across various segments of the oil and gas industry, including:

(1) Crude Oil Storage: Sludge accumulates in storage tanks over time, and decanter centrifuges are used to dewater this sludge, recovering valuable oil and reducing waste disposal costs.

(2) Refining: During the refining process, oily sludge is generated in different stages. Decanter centrifuges help in separating the oil and water, allowing for the recovery of usable oil and reducing the volume of waste.

(3) Drilling Operations: In oil drilling operations, drilling mud and cuttings generate oily sludge. Decanter centrifuges are employed to separate the oil and water from the solid particles, ensuring that the waste is minimized and the recovered oil can be reused.

(4) Oil Recovery from Contaminated Sites: Decanter centrifuges are also used in environmental remediation projects, where oil-contaminated soil or water is treated to recover oil and dewater the sludge, reducing the environmental impact of oil spills.

Conclusion

Decanter centrifuges have become indispensable in the oil and gas industry, offering an effective solution for the dewatering of oil sludge. Their ability to handle complex sludge compositions, operate continuously, and recover valuable resources makes them a crucial technology in managing oil sludge. As industries continue to prioritize sustainability and resource efficiency, the role of decanter centrifuges in oil sludge dewatering is likely to grow, contributing to more environmentally responsible and economically viable operations.