Product Features

Product Features

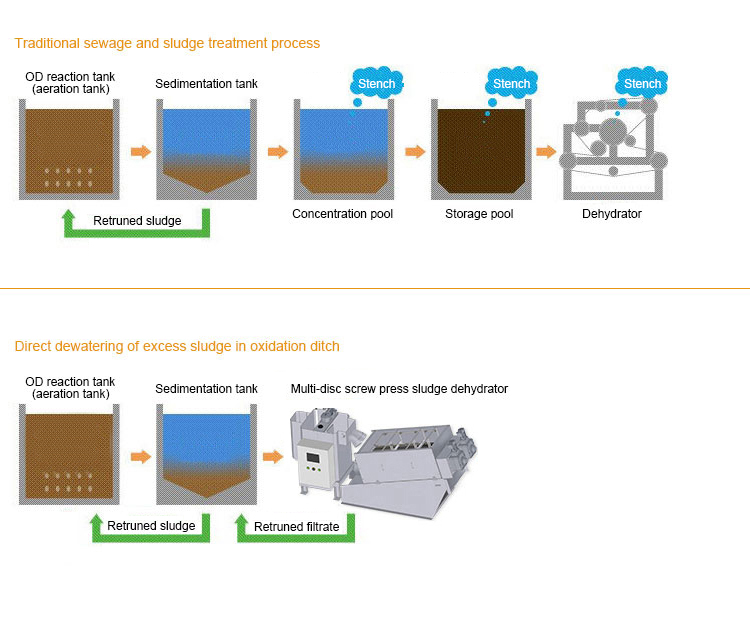

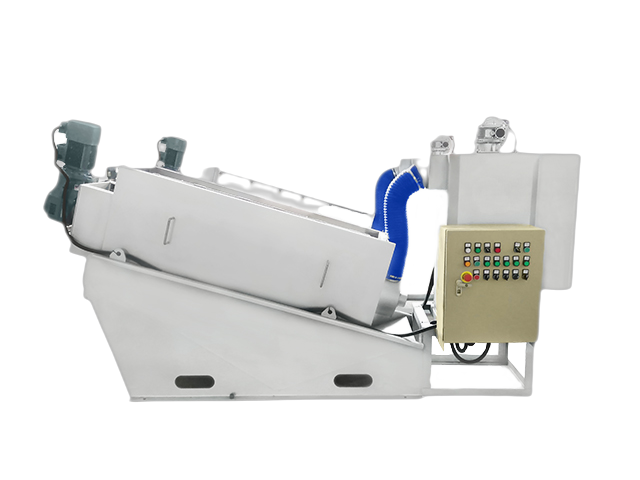

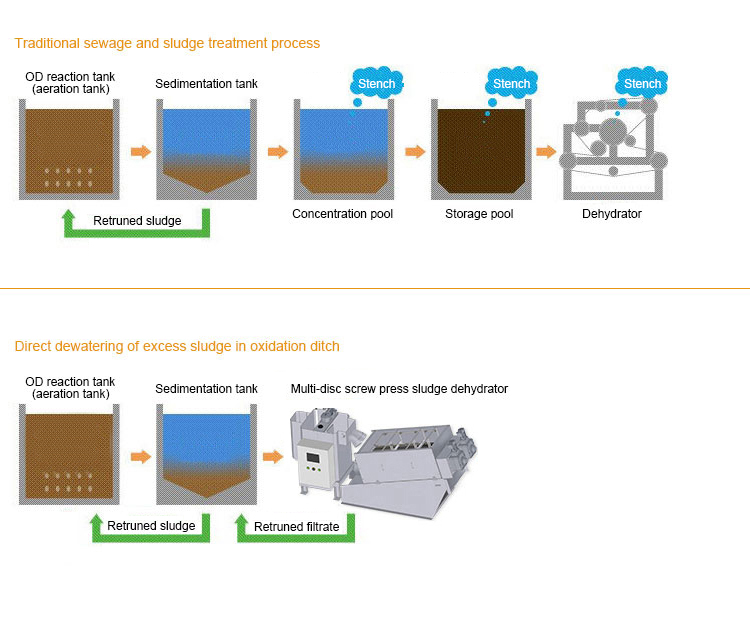

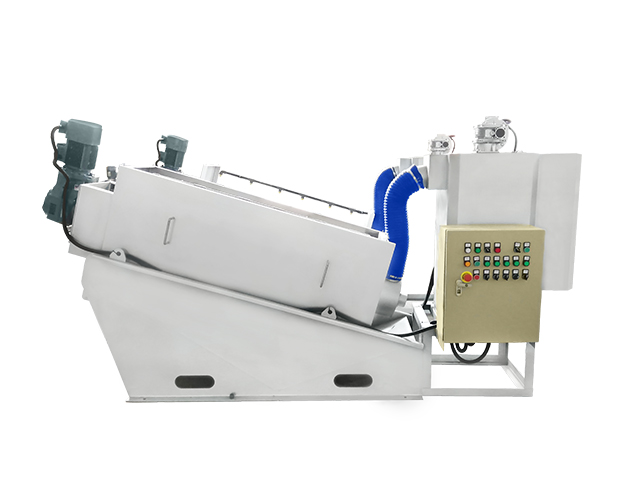

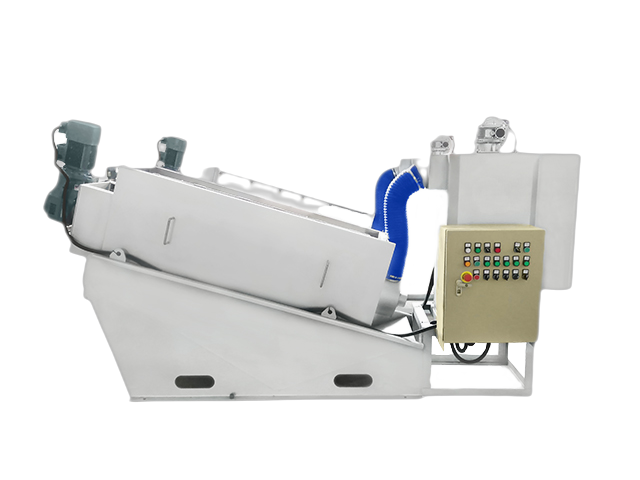

Multi-disc screw press sludge dehydrator is a new type of solid-liquid separation equipment, which can extrude sludge through the strong extrusion force produced by the change of screw diameter and pitch, and the tiny gap between the swimming ring and the fixed ring. It has the advantages of pollution-free, anti-wear, low energy consumption and simple operation, which can achieves the goal of high efficiency and energy-saving dewatering, reduces the sedimentation tank and sludge concentration tank, and saves the construction cost of sewage station.

The product has the following features:

1.Be good at treating oily sludge.

Compared with the traditional sludge dehydrator, the self-cleaning structure of screw press is not easy to cause the clogging of filter seams, and even the oily sludge can be easily treated.

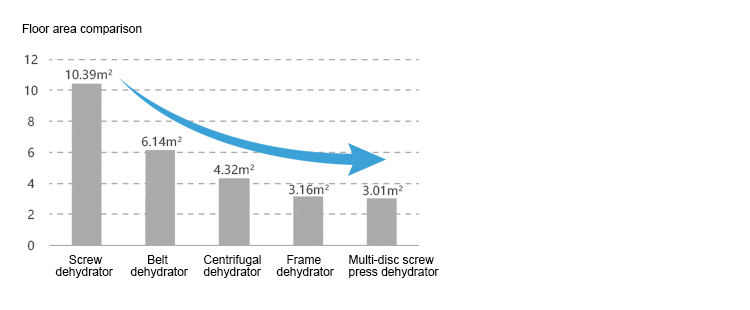

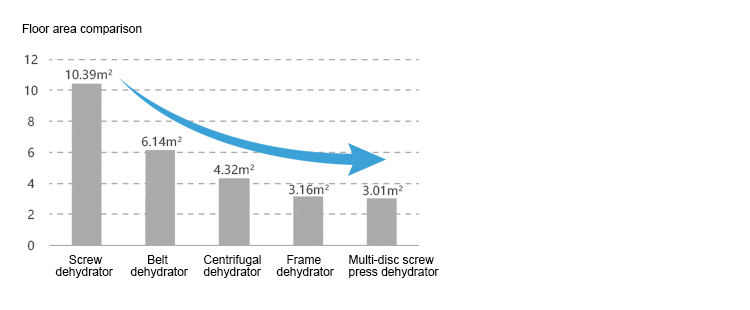

2.Compact design and space saving.

Compared with the traditional sludge dehydrator, the dehydration part, flocculation mixing tank and electronic control cabinet of the multi-disc screw press sludge dehydrator are designed in a trinity, it has the advantages such as convenient installation, small area, strong compatibility with auxiliary equipment, and easy to replace the original equipment.

3.Simple operation and maintenance.

It can realize 24-hour automatic unattended operation through various induction devices, and at the same time, it has few daily maintenance projects and simple maintenance operation.

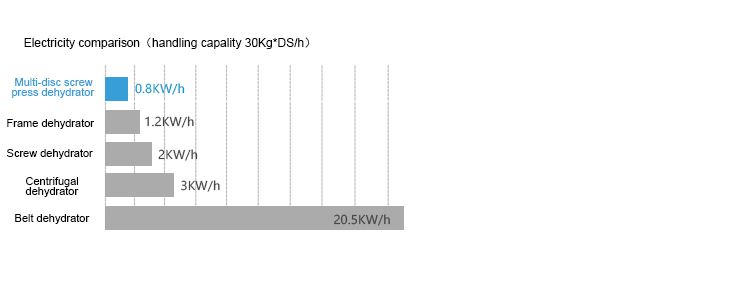

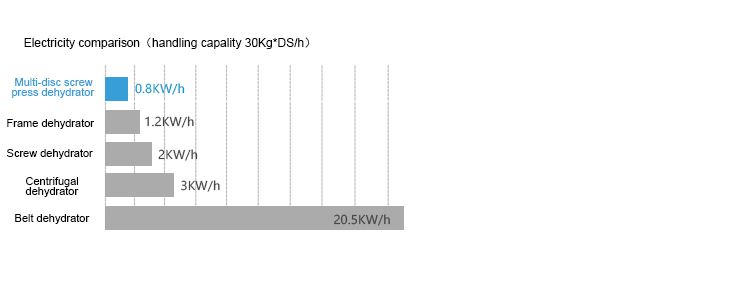

4.Power saving.

As the core component of the screw press, the rotational speed of the spiral shaft is 2-4 rpm. Because of the low-speed rotation, the power consumption is very low, under the same processing capacity, the power consumption of the screw press is only 1/20 of that of the belt dehydrator.

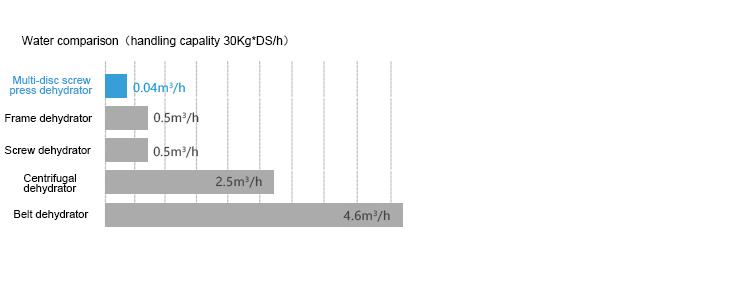

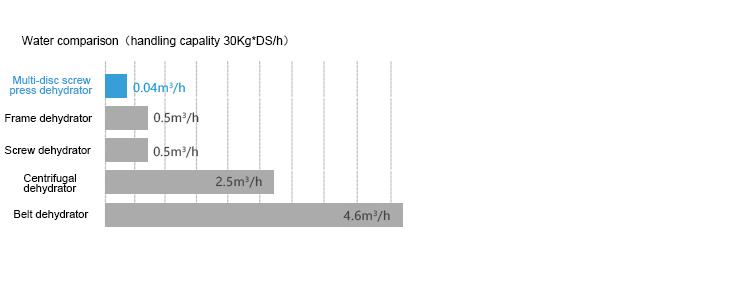

5.Water saving.

Because of the self-cleaning structure prevents the filter from blocking, a large amount of cleaning water was saved, at the same treatment capacity, the water consumption of the screw press is only 1/115 of that of the belt dehydrator.

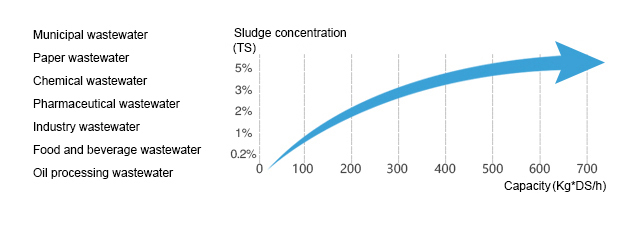

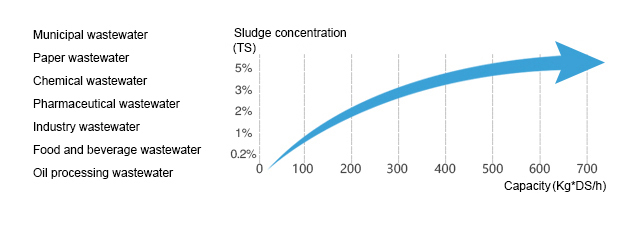

6.Wide scope of application.

It is widely used in the following industries: municipal sewage, tap water, industrial wastewater, food, beverage, animal husbandry, chemical industry, machinery manufacturing, metal processing, petroleum, printing and dyeing, washing,papermaking, etc.

Operating Principle

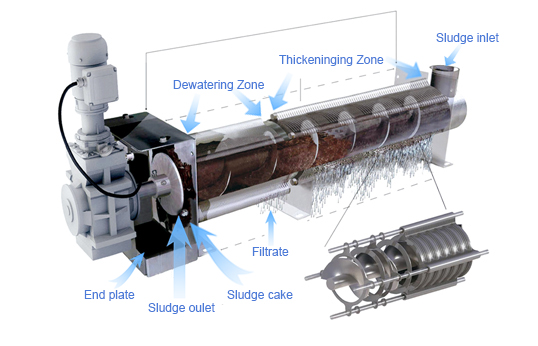

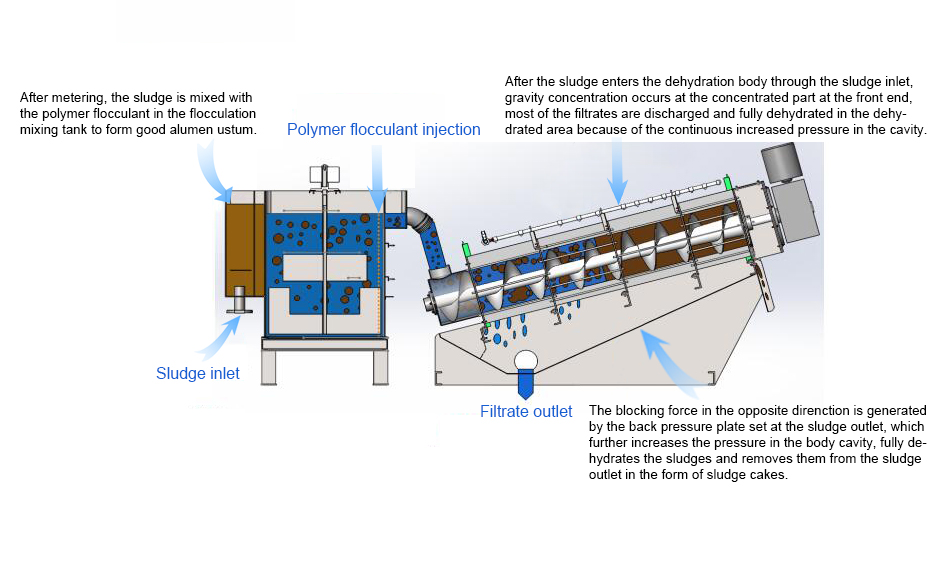

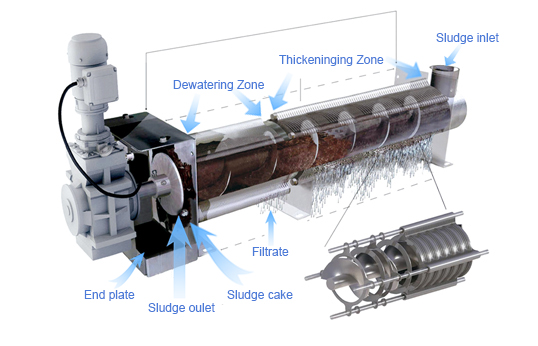

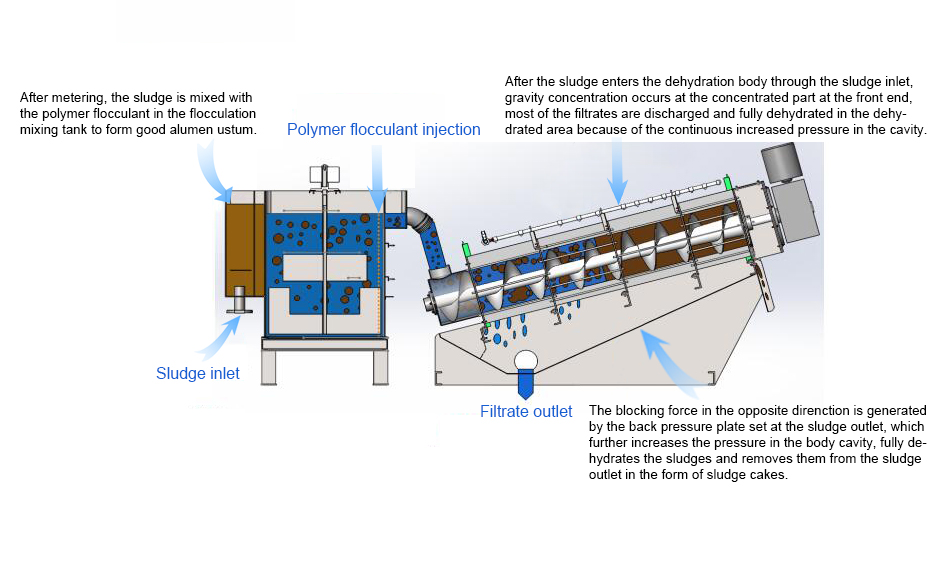

The main body of the dehydrator is a filter device formed by a fixed ring and a swimming ring overlapping each other and a spiral shaft running through them.The former part is the concentration part and the latter part is the dehydration part.

A small moving gap is formed between the fixed ring and the swimming ring, it filters the filtrate. The inner cavity formed by spiral axis and ring plate is filled with flocculation particles, as the end back platen rotates, it delivers and extrudes to form sludge cakes.

As the spiral axis rotates and pushes, it keeps moving with the swimming ring to clean up the gaps and prevents clogging.

When the equipment is running, the sludge enters the sludge inlet, pushed by the helical shaft blades, and concentrated by gravity in the enrichment section to be transported to the dehydration section. In the process of moving forward, with the gradual reduction of filter slot and screw pitch, as well as the blocking effect of the back pressing plate, the sludge generates internal pressure, and the volume is continuously reduced, so as to achieve the purpose of full dehydration.

Product Features

Product Features